Beijing Worldia Diamond Tools Co., Ltd. (namely Worldia)is a

national hi-tech enterprise established in Zhongguancun Science and

Technology Park in China in 2006. Worldia is a professional

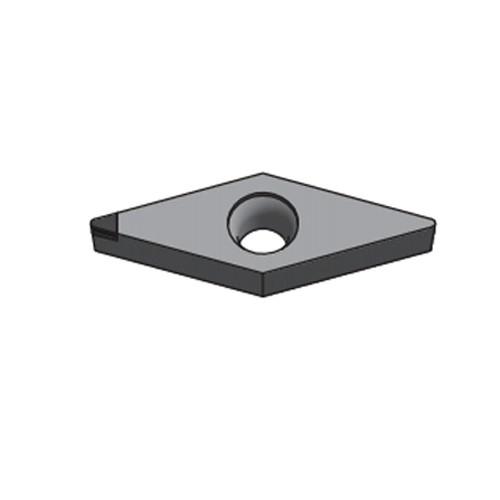

manufacturer of glass cutting tools, PCD/PCBN cutting tools,

diamond die blanks, saw blades, and a CVD diamond line of products.

We are dedicated to the R&D of advanced production technologies

and equipment in addition to manufacturing a wide variety of super

hard cutting tools. The cutting tools we provide have been widely

applied in automotive, electronic, new energy, and other

industries. We have been rewarded with numerous patents. Our

purpose is to solve processing problems for customers and enhance

their competitiveness.

We manufacture solid carbide cutting tools with a number of

five-axis CNC linkage grinders, tool inspectors, HAIMER dynamical

balancing machines, ZOLLER tool setting gauges, and other

industrial high-end equipment and instruments. We specialized in

providing professional services including R&D, manufacturing,

regrinding, and technical services.

At Worldia, we employ unique designs and sophisticated

techniques to ensure the high precision and reliable quality of our

super hard cutting tool and are now leading in carbon processing

cutting tools and other cutting tool industries. Today, our high

precision cutting tool, PCD/PCBN roller cutting tool, PCD inserts

specially used for cutting wind turbine blades and other products

are increasingly used in many fields, such as new composite

materials (like nonferrous metal, ferrous metal, tungsten carbide,

plastic, fiberglass, etc.), fiber reinforced plastics (FRP),

rollers, auto parts, stone engraving, and more.

In manufacturing our diamond die blanks, we creatively use

precision grinding and polishing technologies. The application of

cold press-fit techniques instead of hot pressing prevents damage

to PCD internal structure caused by high temperature.

Worldia also manufactures PCD and carbide saw blades, CVD

diamond line of products, diamond nozzle, lapping and polishing

machines, glass cutting machine, and other products, and is

dedicated to offering customized and complete cutting solutions.

As for super hard materials processing, we provide high

precision lapping and polishing, laser cutting, and rework of PDC

cutters, in addition to OEM/ODM services. Hence our products are

popular in Southeast Asia, Western countries, and others.

Our values define how we do business and interact with our

colleagues, partners, customers, and consumers. Our four core

values are integrity, innovation, service, and efficiency. As we

expand into new markets, recruit new talent, and face new

challenges, these guide our people in the decisions and actions

they take every day.

We are dreamers and innovators!

We are now made in China and hope we can grow with you

together.

Our vision is to redefine the concept of“made in China".

Our mission is to focus on high-end super hard tool

manufacturing, dedicated to quality changes in the world.